What is Iron/Steel with chrome plated?

high-quality-chrome-plated

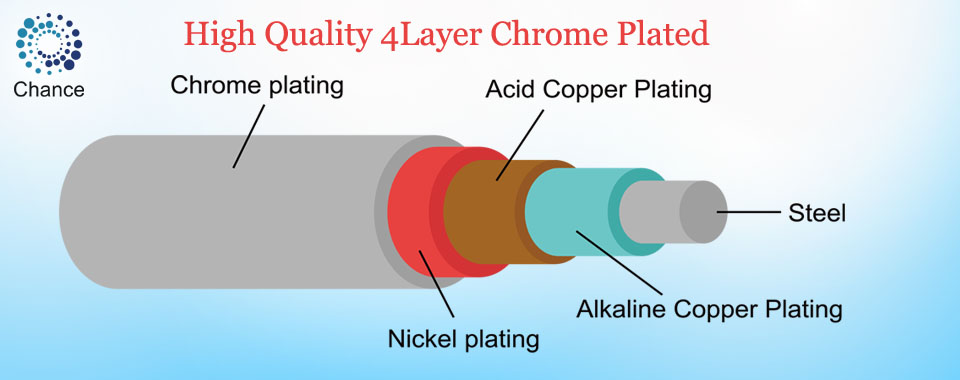

Surface finishing is a frequently used method of decoratingvisible metal surfaces. Chrome plating with copper-nickel chrome is the coatingsystem of choice when good corrosion protection and excellent optics

areequally important.

When using the Cu-Cu-Ni Cr combination, the flexibility of thecopper undercoat compensates possible

tension between the component and thesurface layer. Furthermore, it guarantees optimum adhesion, levels off andforms a corrosion barrier within the layer system. The copper plating alsoinfluences the subsequent glossy effect of the following layers.

Depending on the selected thickness and layer combination,Nickelprovides a high degree of anti-corrosion protection.

The electrolytic chrome is the final layer to be applied. Chromeis very hard, durable and resistant to tarnishing. Decorative chrome platingimplemented in this combination can result in glossy chrome surfaces. As alayer system, copper, nickel and chrome are an unbeatable trio.

Alkaline Copper Plating + Acid CopperPlating: The effect smoothens the surface of the wire, making the wire moresmooth

Nickel plating: key anti-rust function

Chrome plating: Strengthens thehardness to protect the nickel layer and the copper layer from damage and increasethe brightness of the product.